But increased patient autonomy is acceptable only if therapeutic procedures are repeatable, reliable and effective. In the case of parenteral drug delivery, this level of performance will only be achieved if sufficient development effort is focussed on the delivery device; as PDA Europe senior vice president Georg Roessling has noted, stakeholders sometimes forget that the delivery device is the ‘drug to patient interface’, and therefore equally as important as the drug being delivered.

From a regulatory point of view, a ‘usable’ device is one which is easy to use correctly, difficult to use incorrectly, and therefore can improve compliance. As this imperative drives developments forward, effort will increasingly focus on those elements of designs which can be enhanced in order to improve usability while maintaining the parallel objectives of technical functionality and acceptable cost. Product design is therefore a sophisticated balancing act, demanding a thorough understanding of all the factors involved.

Naturally, the characteristics and demands of the therapy, such as dose size, viscosity and storage issues (such as refrigeration) guide choice of primary container and device mechanism, while dosing regimen and market size influence the manufacturing approach and hence cost of goods. The resulting product must however also reflect user needs. These include therapy-specific requirements and consideration of the cognitive burden imposed on the user, and of the environment in which the device will be used. All of this must take place within an increasingly stringent regulatory environment. ‘Understanding’ is the overarching requirement; understanding regulations, therapies, technologies, markets and manufacture, and of course perhaps the least predictable element, the user.

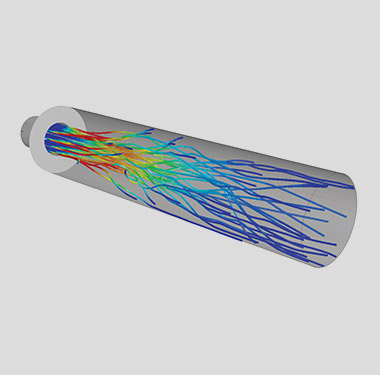

Moving forward, a number of technology developments are likely to prove influential. Pre-fillable glass syringes designed specifically for autoinjector use, for example, promise significantly better dimensional control and tighter tolerances than ‘traditional’ products. COC and COP pre-fillable syringes offer impressive levels of dimensional precision with good barrier performance and robustness without the tungsten contamination issues encountered with glass. New siliconisation inspection systems enable consistent syringe lubrication and reduced silicone levels, while innovative new syringe treatment processes promise reduced friction without any silicone. These improvements will enable predictable engineering, capable manufacture and robust design for injection devices.

Parenteral delivery opportunities are expanding and the growing technology spectrum both supports and stimulates this expansion. For example, large volume delivery and high viscosity formulations enable reduced administration frequency, reduced discomfort and increased convenience. The ready to use needle-free devices can readily deliver high viscosity formulations, and electronically enabled delivery devices (EEDDs) include patch-pumps able to deliver several ml over 30 minutes or longer, and injectors which compute dose titrations, remind users to take therapy and automate the delivery.

For any therapy needing parenteral delivery, without a device there is no product. For a successful product the pharmaceutical, user, manufacturing and reliability requirements all have to be right – and that’s the challenge we thrive on!