Using mRNA as cancer therapy

Messenger Ribo Nucleic Acid (mRNA) carries a cell’s instructions to create proteins. mRNA from a disease is injected into cells to instruct them to create proteins specific to that disease, inducing a targeted immune response.

mRNA technology is now being used for cancer therapy to attack tumour cells. mRNA technology is an effective cancer treatment as it generates proteins specific to a person’s tumour.

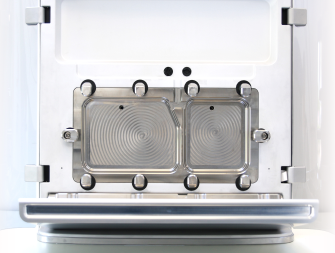

Since everyone’s cancer is unique to them, mRNA must be manufactured for each patient. It is also very unstable and easily broken down by the human body. By injecting it into lipid nanoparticles (LNP) the mRNA can be protected until it reaches the cancer cells.

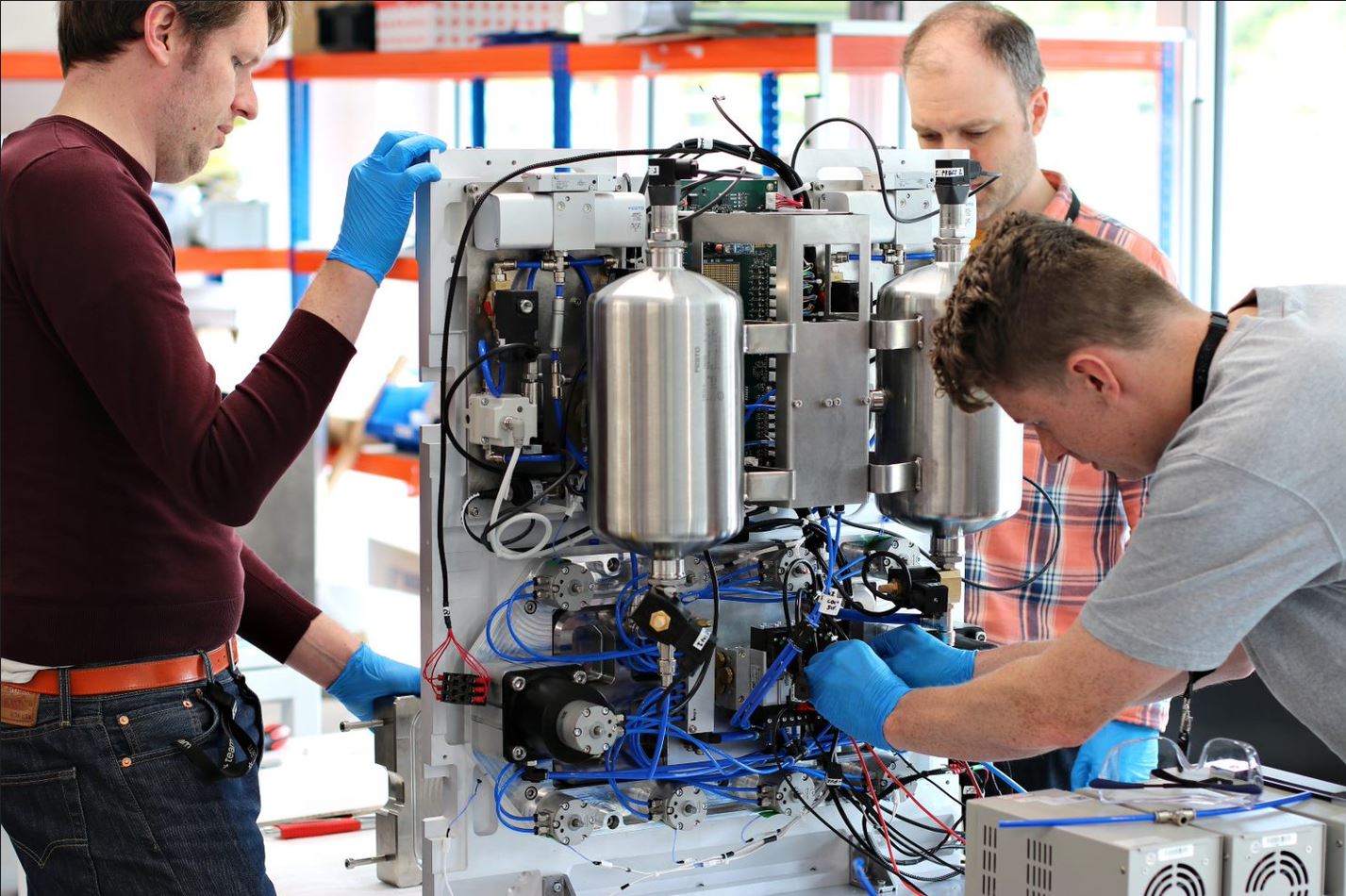

Drug delivery Industrial design Mechanical engineering Software engineering User experience